Sunrise (Ningbo) Precision Metal Parts Inc.

Available Specification

Kennametal HDD weld-on teeth: RT1, RT2, DT50, DT87, BR1, BR2, BR3, BR4, U7, U7L, CJ2

Contact us for more specification. We can also customize upon request.

Product Application

For horizontal directional drilling back reamers.

Our Expertise

1.Selected tungsten carbide tips ensure best cutting performance.

2.Hard & tough steel body.

3.Assured high brazing strength.

4.Rigorous quality control system is performed for consistent quality.

-

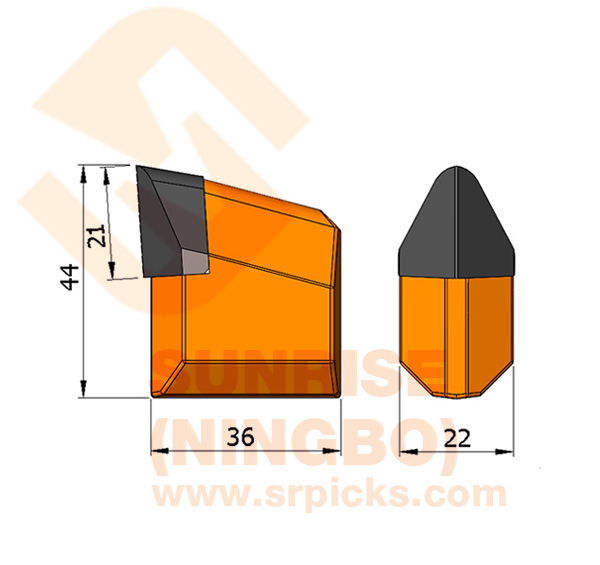

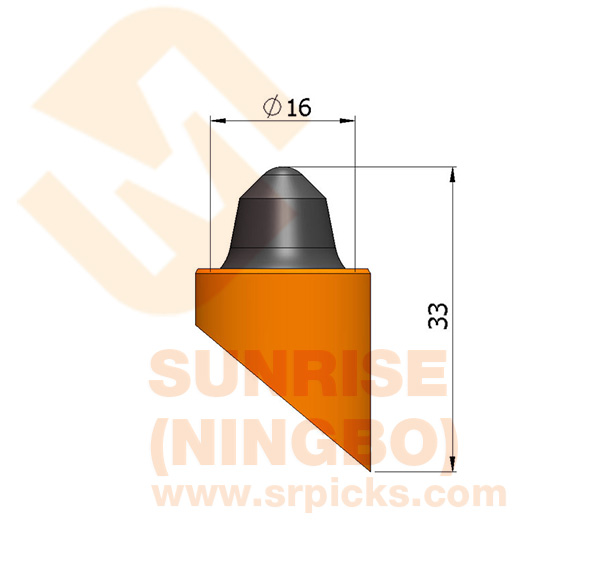

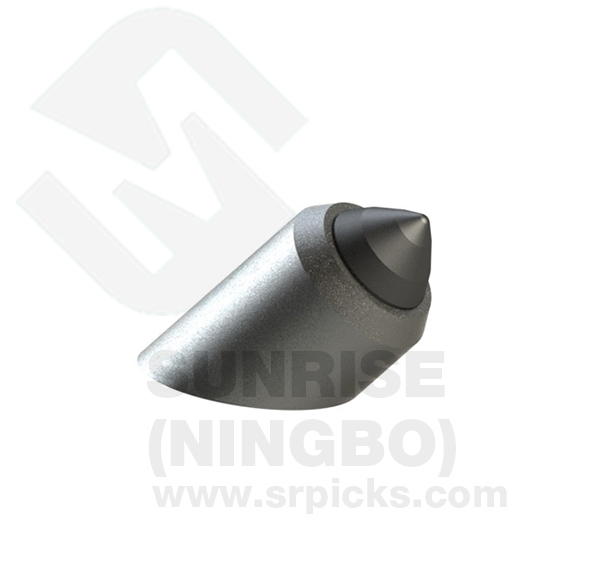

- DHKW01 HDD directional drilling welding teeth

- (Equivalent to RT1)

For soft to medium hard rock drilling conditions

-

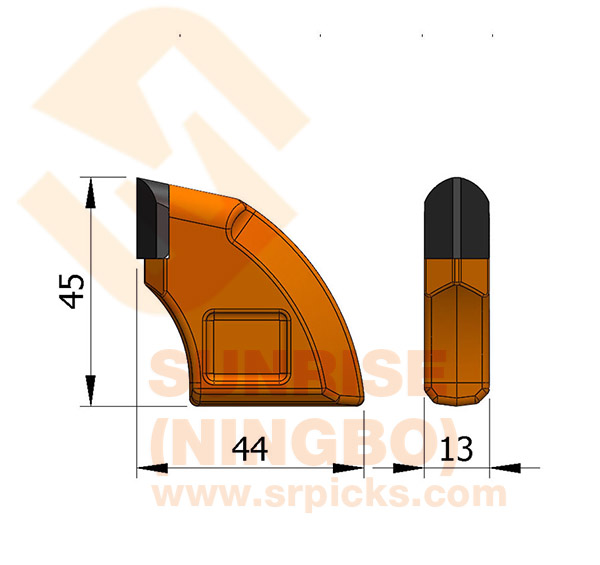

- DHKW02 Flat cutter tools weld on cutter teeth

- (Equivalent to RT2)

For soft to hard rock drilling conditions

-

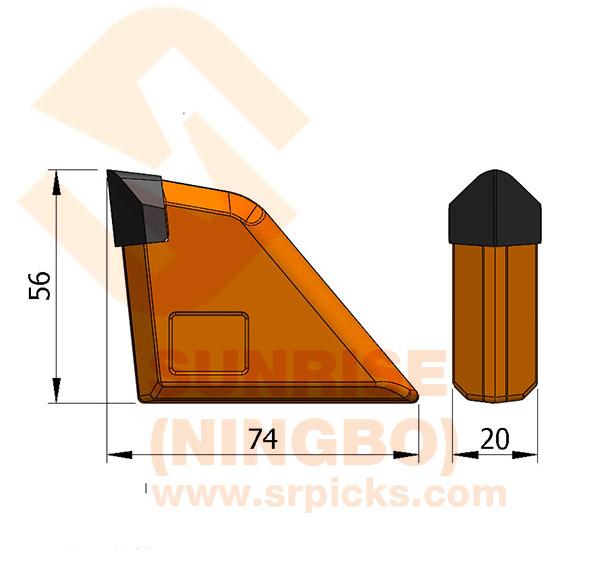

- DHKW03 HDD bits weld on carbide teeth

- (Equivalent to DT50)

For soft to hard rock and concrete drilling conditions

-

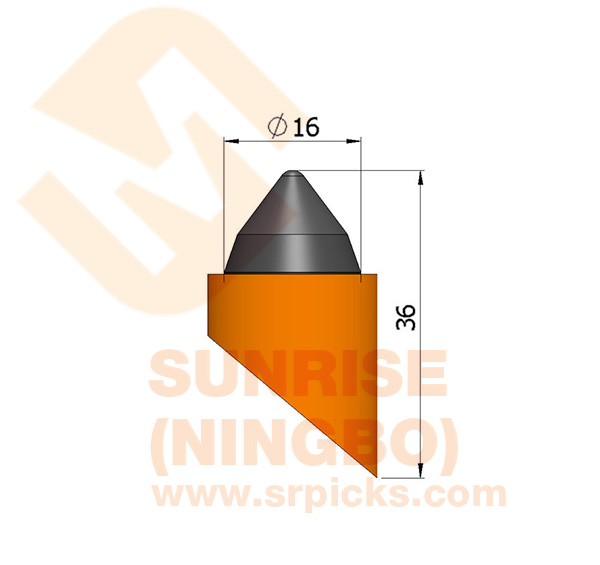

- DHKW04 Directional drilling weld on bits

- (Equivalent to DT87)

For hard rock and concrete drilling conditions

-

- DHKW05 HDD weld on tools welding bits

- (Equivalent to BR1)

For all cutting conditions

-

- DHKW06 Horizontal directional backreamer bits

- (Equivalent to BR2)

High penetration tip

Tips for better penetration in hard cutting conditions

-

- DHKW07 Weld-on tools bits back reamer teeth

- (Equivalent to BR3)

Tips for high penetration in hard cutting conditions

-

- DHKW08 HDD drilling bits weld on teeth

- (Equivalent to BR4)

Use on high horsepower machines for abrasive conditions

-

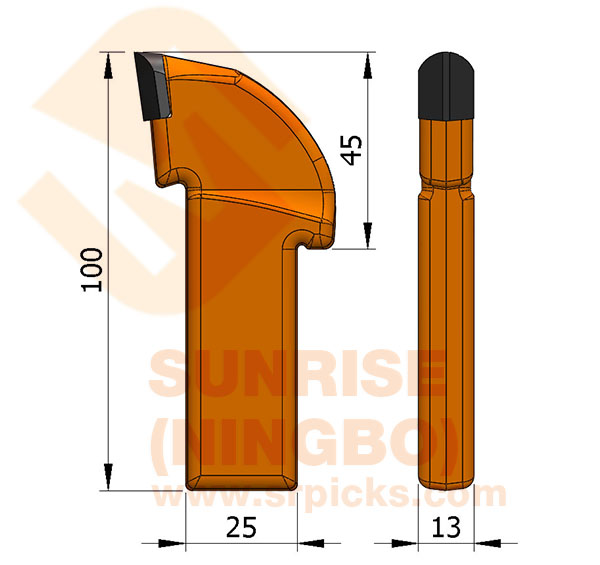

- DHKF1301 Tungsten carbide flat picks

- (Equivalent to U7)

For soft to hard boring conditions

Apply on core barrel

-

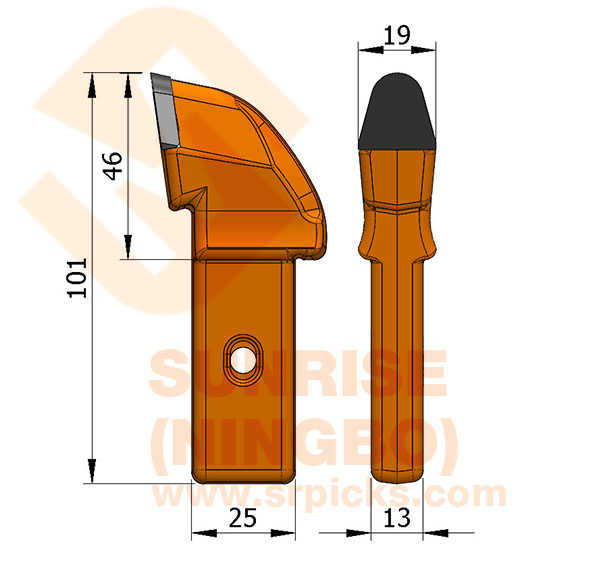

- DHKF1302 Core barrel flat cutter teeth

- (Equivalent to U7L)

Apply for hard rock core barrel boring conditions

-

- DHKF1303 Blade cutter picks trenching flat bits

- (Equivalent to CJ2)

For extremely hard ground boring holes conditions