Sunrise (Ningbo) Precision Metal Parts Inc.

Available Specification

Kennametal welding teeth: RT1, RT2, DT50, DT87, BR1, BR2, BR3, BR4

Contact us for more specification. We can also customize upon request.

Our Expertise

1.Selected tungsten carbide tips ensure best cutting performance.

2.Hard & tough steel body.

3.Assured high brazing strength.

4.Rigorous quality control system is performed for consistent quality.

-

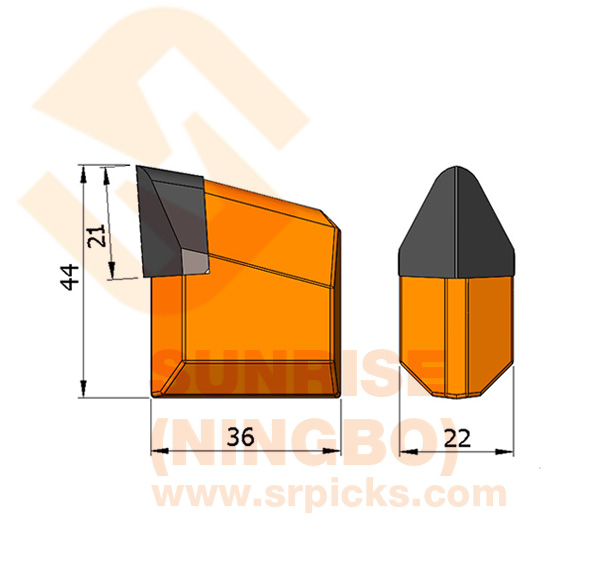

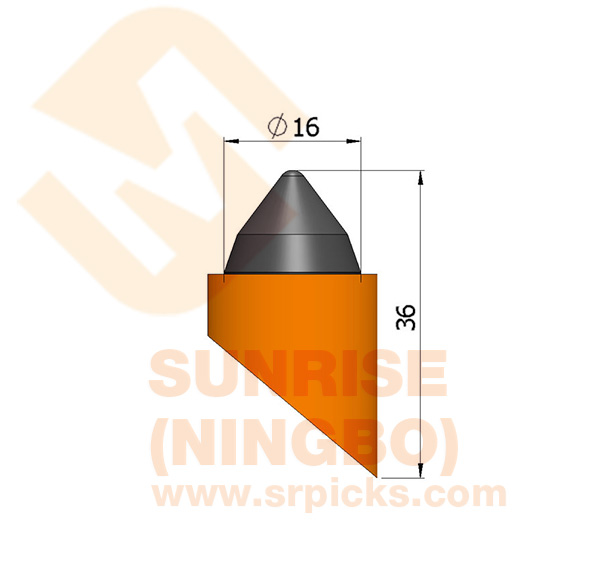

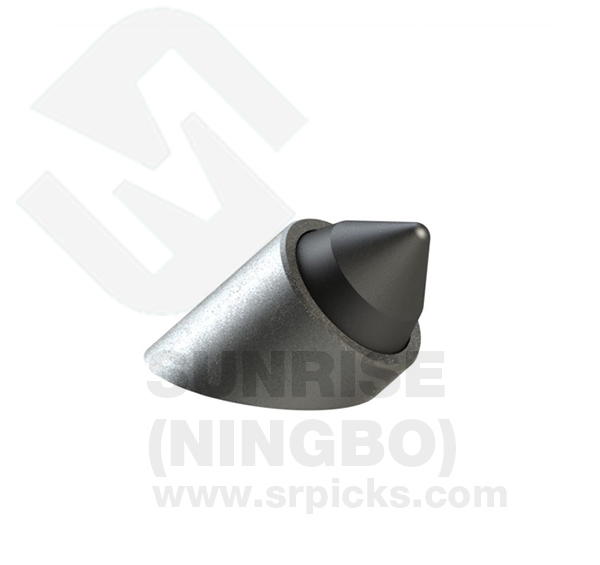

- T0KW01 Backreamer teeth weld-on cutter bits

- (Equivalent to RT1)

For soft to medium cutting conditions

-

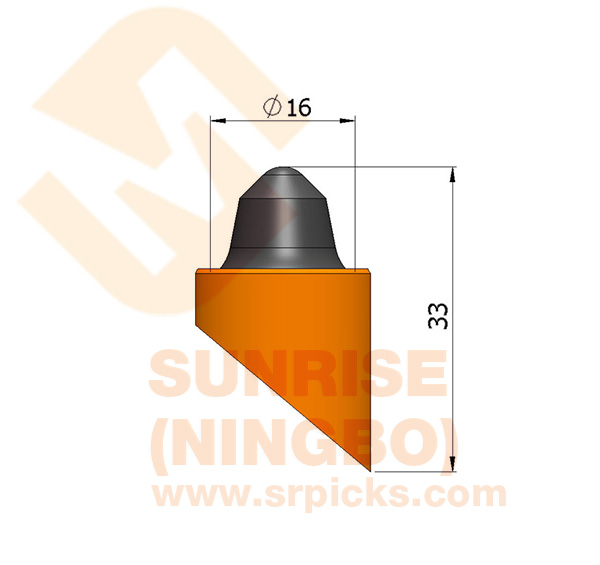

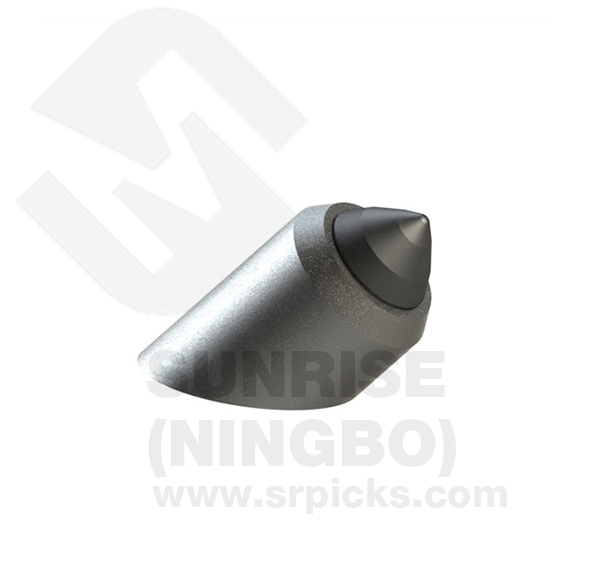

- T0KW02 Directional drilling machine bits

- (Equivalent to RT2)

For soft to hard cutting conditions

-

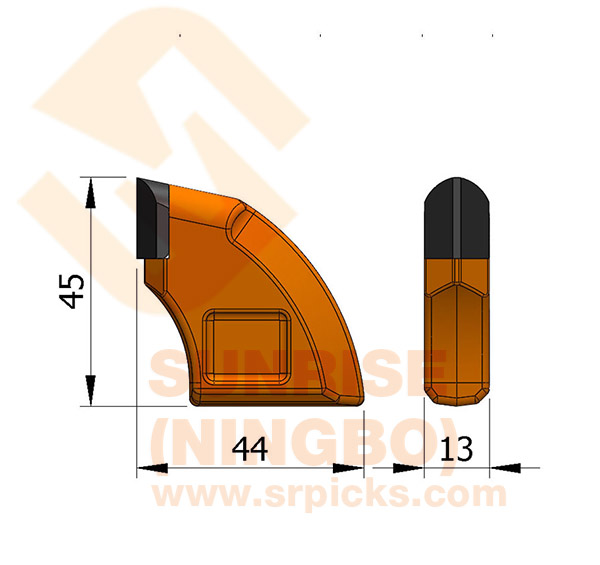

- T0KW03 Weld on trencher flat teeth

- (Equivalent to DT50)

For soft to medium cutting conditions

-

- T0KW04 Back reamer trenching teeth

- (Equivalent to DT87)

For soft to hard cutting conditions

-

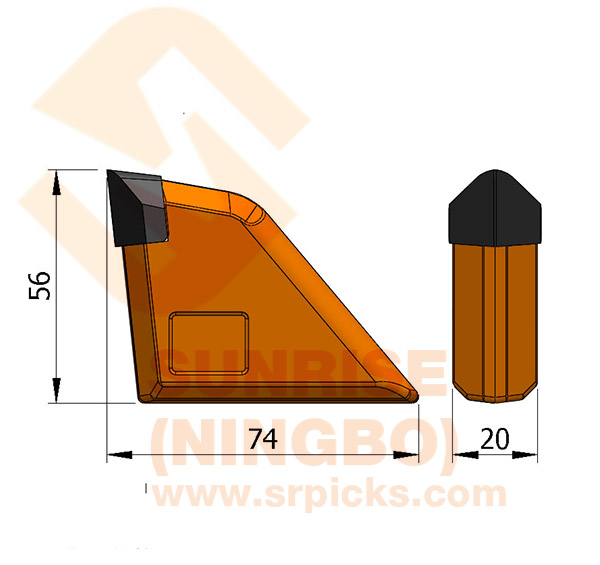

- T0KW05 Back reamer weld-on bits

- (Equivalent to BR1)

For all cutting conditions

-

- T0KW06 HDD Weld on cutter teeth

- (Equivalent to BR2)

Tips for better penetration in hard cutting conditions

-

- T0KW07 Trenching tools reamer bits

- (Equivalent to BR3)

Tips for high penetration in hard cutting conditions

-

- T0KW08 Welding trenching bits

- (Equivalent to BR4)

Use on high horsepower machines for abrasive conditions